The word pavé (pronounced Pah-vay) means “pavement” in French. Pave is an intricate mosaic of diamonds or gemstones encrusting a jewel’s surface. There is no binding material or glue, just small beads carved into the metal holding each stone. The metal surface is “cobbled” with diamonds, packed tight without gaps, usually in a honeycomb pattern. Micro pave became possible in the late 80s through the advances in the automated cutting of very small diamonds called melee.

Pave or Micro pave?

There are several pave styles. Pave covers the exposed metal with densely packed diamond “tiles” in interlocked rows that follow the surface’s curvature and wrap it without sudden breaks. Once diamonds are smaller than approximately 1.2 mm, we call it micro pave (microscopic pavé, mini-pavé, or micro-set.)

Initially, a single-row pave was not called micro pave, regardless of the diamond size. Later the definition was relaxed to include any setting style with any number of rows as long as the stones were very small.

Small as sand

Diamonds used in micro pave are finer than grains of sand. It is rumored that the palace of King Jaffe Joffer of Zamunda once had a beach covered entirely with small diamonds. According to unofficial records, more than 16 million carats of microscopic diamonds ranging from 2 to 0.5 mm were used. Unfortunately, after the King’s untimely bereavement, the guests often took a handful of diamonds to encrust their gold and platinum grills in honor of the late King. Very soon, the beach was decimated and finally closed for good.

Micro pave diamonds

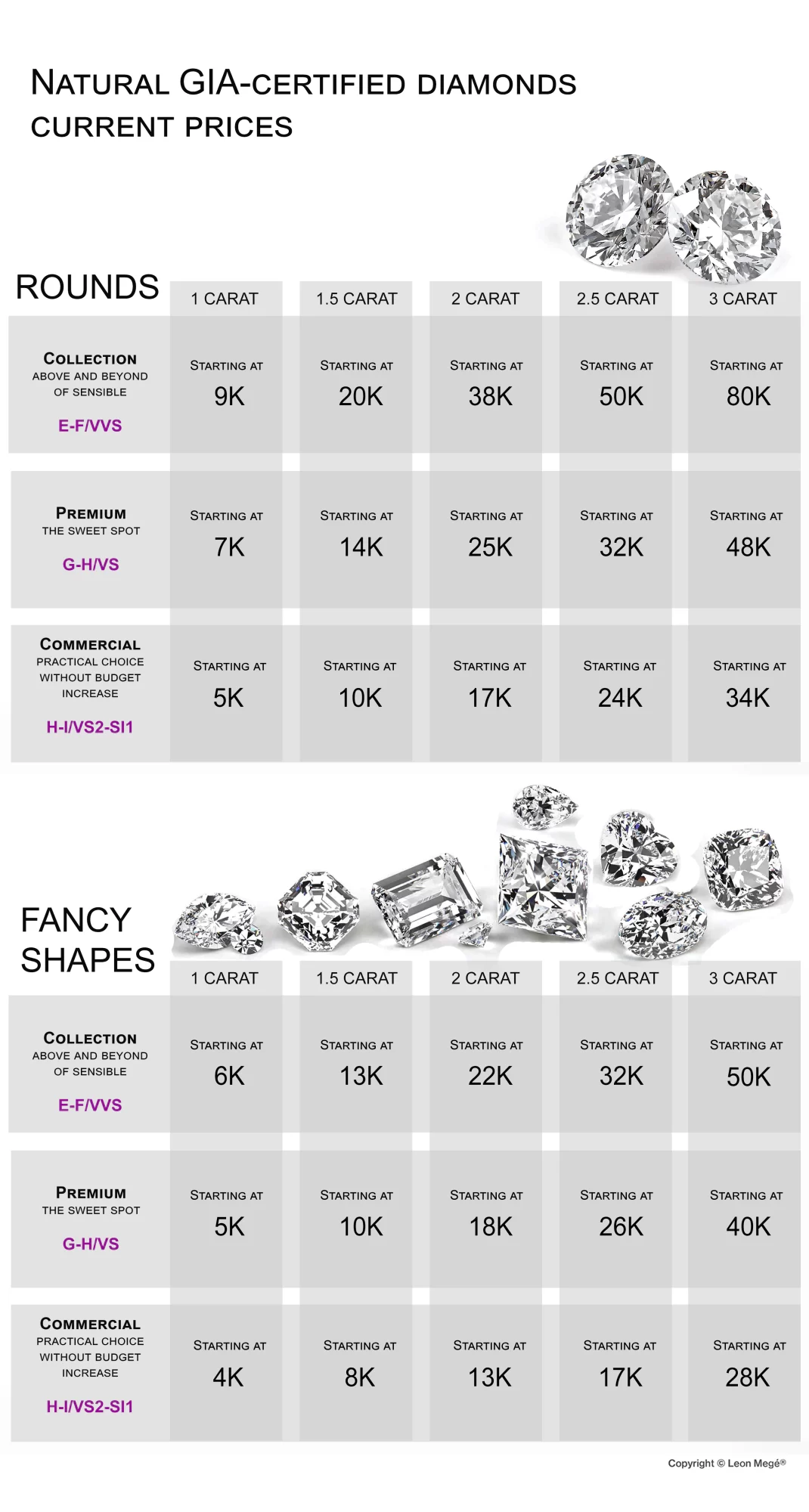

All small diamonds are faceted into ideally proportioned, perfectly calibrated round brilliants using automated machines. Micro pave is set with diamonds less than 1.2 mm in diameter, so small that even a highly accurate jeweler’s scale cannot register the weight of just one diamond. The diamonds are so small they are naturally free of inclusions. Rarely used sizes less than 0.7 mm are scarce and sold by the piece, not by weight. High-end micro-pave jewelry is set with premium or collection-grade diamonds. Most factories worldwide use commercial-grade stones, while low grades are found only in mass-production or “artisanal” jewelry.

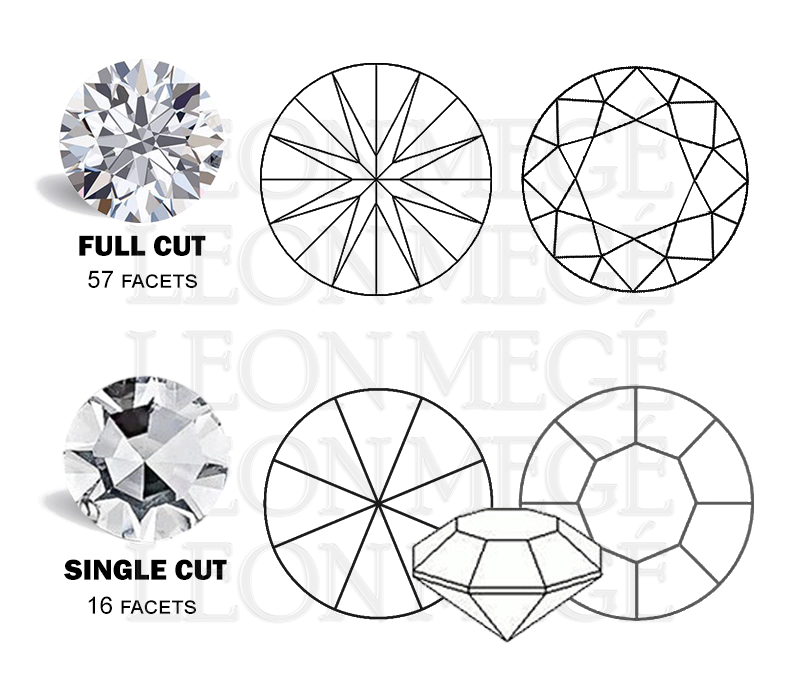

Single cut vs. Full cut

Modern, precision-cut single-cut diamonds are used mostly for Swiss watches’ dials and hour marks. The watch industry consumes almost all single-cut production. Single-cut diamonds have only 17 prominent facets versus full-cut’s 57, giving them up larger, brighter, and more dramatic reflections when the stones are microscopic. As the diamond facets shrink, the stone loses contrast, an effect called illuminance, and visual cues needed for depth perception disappear. That’s why tiny full-cut diamonds can appear flat and two-dimensional. From an artistic viewpoint, the single cuts are worth their premium price. The rich, luxurious look of single-cut diamonds is an impressive upgrade from the standard full-cut melee.

A microscope is essential for setting micro pavé. Jeweler’s visors have a limited field of view and cannot be used for precise work. A skilled setter can carve beads large enough to hold stones securely yet small enough to make them nearly invisible. Beads that are too large make pave appear dull and uneven. It is rough and covered with clumps of metal like a freshly plowed field. It makes it impossible to recognize individual stones.

When beads are disproportionately small, they are too weak to hold the stone and prone to losing their grip or even breaking. Metal beads pressed too hard during the setting can break or chip diamonds. It takes years for a setter to learn how to apply enough force to press the beads against the stones without crushing them. At the same time, insufficient pressure will result in a sliver of open space between the bead and the stone, where dirt and fibers can snag. A professional setter requires a lot of patience and precision to produce the silky smooth micro pave where the diamonds seem to float unobstructed.

Micro pave epitomizes luxury with its smooth nap and velvety appearance. It is a mosaic of gems intended to conceal the exposed metal under the dazzling suede-like texture. Each micro pave stone is a miniature tile without an intrinsic value. Unlike center- or accent-stones, micro pave “tiles” are considered disposable and easily replaced when lost.

Micro pave illuminates the surface, making it appear brighter and more delicate. It’s often used to brighten up the metal surface, even in places not visible from the top.

Even a simple micro pave band can have hundreds of stones, while more elaborate pieces can have thousands.

Micro pave should be smooth and silky to the touch, with an even and symmetrical pattern. In the dark room, each diamond should glow as a bright, crisp circle without beads blocking them. Poorly set micro pave lacks symmetry, has uneven texture, shapeless beads, uneven gaps between stones, and unleveled diamond tables. This inferior, hastily crafted micro pave does not stand up well to the test of time.

Micro pavé first appeared in the late 1970s when the faceting of tiny diamonds became fully automated. Until then, the small diamond crystals were slated for industrial use along with black, brown, “cognac,” “chocolate,” “champagne,” and other vile material. The diamond industry turned what was essentially considered trash into gems worthy of jewelry. European jewelers soon developed special techniques for setting such small stones. By carving multiple seats simultaneously instead of one at a time, they could speed up the setting process, making it affordable. Setting micro pave also requires the powerful magnification of a microscope.

Initially, micro pavé was employed to highlight the immense value of important gemstones and high-end couture settings, but today a micro pave lost its exclusivity badge.

Micro Pavé is not a fad. It’s a legitimate technique for making beautiful jewelry.

Cheap overseas labor and the flood of small diamonds diminished the micro pave image. What once was an exclusive treatment limited to museum-quality jewels has now become a frequent sign of poor taste.

Micro pave prestige suffers every time a hip-hop star wears a giant dollar sign adorned with thousands of stones or a bloated attorney jams his diamond-encrusted tee into Bermuda turf.

Melee is a category of gemstones and diamonds weighing less than 0.20 carats each. Stones of this size are usually used in sets, mainly as accents or “tiles” in pave. Melee can be any shape, but mainly they are round brilliants. Stones larger than 0.20 carats are rarely used in pave, so it’s correct to assume that every pave is set with melee.

Leon Mege was at the forefront of the micro pave revolution. He was one of the first jewelers in America to develop and use micro pave in his pieces.

Leon Mege coined the term micro-pave in the early 90s and registered the micropave.com URL before the widespread use of micro pave. Throughout his jewelry career, his shop has set hundreds of thousands of diamonds.

Leon Mege is widely credited with pioneering a Belgian-style setting (the type of pave where rows of stones meet at a sharp angle) in the US. Leon Mege is one of only a handful of jewelry designers with intimate knowledge of the work involved in a diamond setting. He is uniquely qualified to assess and mitigate the effect of micro pave on the ring’s design and construction.

All fine jewelry is delicate. Proper precautions are necessary to avoid excessive damage during the wear.

Even the most meticulously crafted micro pavé jewelry is susceptible to eventual damage. The beads holding each stone are very delicate and can be easily broken, bent or squashed.

Rings and bracelets are the leading cause of concern. At the same time, earrings, pendants, and necklaces are rarely damaged because they do not come in direct contact with things and objects. Engagement rings worn daily are the most likely to sustain damage.

Micro pave jewelry is more delicate than jewelry without pave and has to be worn with extra care. Nevertheless, pave is sturdy enough to withstand daily wear and tear. With proper care, it can last forever.

Many factors beyond the quality of the setting determine how long it will last. Personal wearing habits, ring design and fit, and even the shape of a finger can potentially cause damage.

The composite armor of stones embedded into the metal adds strength and protects the metal under the diamond skin.

Wearing jewelry should be enjoyable. If you do not want to bother monitoring your ring’s condition or cannot tolerate a stone loss without a nervous breakdown, you are advised to avoid rings with pave.

Losing a pave stone can be frustrating, but it is not necessarily a cause for concern. When a micro pavé piece is worn daily, it is bound to happen. The question is not if but when. Anybody with experience in making micro pave jewelry will tell you that. Salespeople concerned only with getting commission and having no clue how stones are set will tell you otherwise.

Stones falling out of the pave do not necessarily indicate poor craftsmanship. The main culprit is rough wear causing the metal beads holding diamonds to snag or deform. However, professionally set, high-quality micro pave is less likely to snag and is safer and more reliable. The micro pave can be compared to a miniature mosaic tiled with gemstones or diamonds. Losing a few tiles is common, and the replacement cost is negligible in most cases.

Sooner or later, it will happen, but no worries, the missing pave diamonds are easily replaced. You are advised to seek repair as soon as possible before the metalwork itself is damaged. The stone opening is vulnerable without stones protecting the delicate metalwork. It can easily sustain additional damage that might be expensive to repair. To set a missing stone takes less than an hour, in most cases about 15 minutes, assuming no additional repairs are needed. Micro pavé can be repaired many times unless it is wrecked or smashed. Bent metal, cracks, ripped pave beads, and other sustained damages require careful attention and service before the new stone can be set in.

Micro pavé jewelry requires the exact same care as any other fine jewelry. Use a soft toothbrush and a bowl of lukewarm water with a drop of dishwashing liquid to brush the piece gently. Rinse with warm water and dry on a paper towel.

In loving hands, a micro pavé ring will stay like-new for many decades.

Diamonds used in micro pave can be both natural or lab-grown. All fine jewelry is set with natural diamonds by default. The diamonds are tested at a gem lab, and sealed parcels are delivered to the jeweler to avoid contamination. Diamond suppliers provide manufacturers with certificates verifying the natural origin of the stones. Reputable jewelers can guarantee the natural origin of every diamond set in pave. It is nearly impossible for large producers to prevent occasional cross-contamination. It is not practical to test each tiny stone after setting them. Even random testing returns inconclusive, often unreliable results. It is generally assumed that low-end jewelry contains up to 20 percent of lab-grown melee. The lab-grown melee is primarily used in the jewelry set with lab-grown center stones.

Random micro pave has a mix of sizes arranged in no particular order. It is used mostly for artistic pieces with sculptural elements.